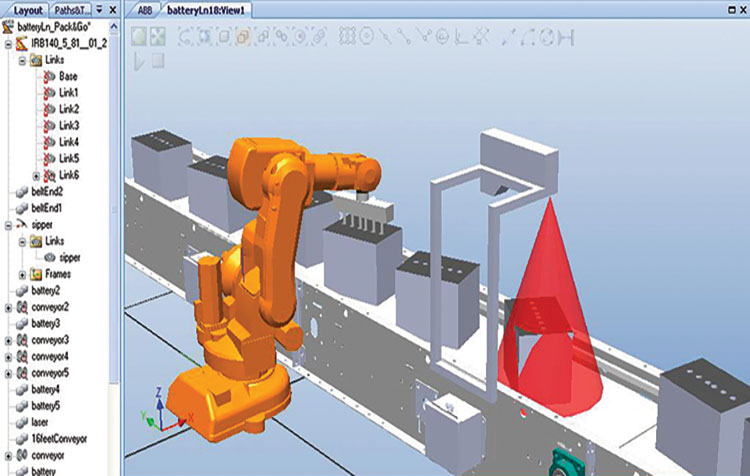

Robotic Simulations

Visualize, Validate & Optimize Your Automation Before It Hits the Floor

At Potent Power System, our Robotic Simulation Services enable manufacturers and automation engineers to virtually design, test, and validate robotic processes before actual deployment. By creating digital models of robotic workcells, production lines, or automation setups, we help businesses reduce design errors, optimize cycle times, and improve system performance — all without touching the shop floor.

Robotic simulations are essential in today’s automation landscape. They provide a risk-free, cost-effective way to evaluate concepts, improve motion paths, avoid collisions, and ensure that robots and supporting systems perform as intended from day one.

What We Offer in Robotic Simulation Services:

At Potent Power System, we offer advanced Robotic Simulation Services that empower manufacturers to virtually plan, test, and optimize their robotic systems before physical deployment. By simulating robotic operations in a 3D environment, we help clients reduce commissioning time, avoid design errors, and improve system efficiency — all while lowering costs and minimizing downtime.

Our simulations replicate real-world working conditions, enabling complete visibility into robot movements, reachability, cycle times, and potential interferences. This ensures smoother automation rollouts, enhanced productivity, and higher ROI from robotic investments.

- 3D Robotic Workcell Modeling

- Offline Programming (OLP)

- Cycle Time & Reach Analysis

- Collision Detection & Interference Checking

- Tool & End Effector Simulation

- Line Balancing & Layout Validation

OUR PREMIUM SERVICES

Why Choose Potent Power System for Robotic Simulation?

Reduce Implementation Time & Cost

Catch issues early and reduce the need for rework during commissioning.

Optimize Robot Paths & Productivity

Improve robot performance with refined motions and efficient sequencing.

Minimize Downtime

Offline programming and validation means less production disruption.

Realistic, Scalable Solutions

Simulations are tailored to match your real-world systems and allow for future scaling.

Cross-Industry Expertise

Experience in automotive, manufacturing, FMCG, packaging, and more.